Oakville Shaker Works

| ||||

| ||||

Oakville Shaker Works

Reproduction

Shaker Boxes

Oakville Shaker Works

Reproduction Shaker Boxes

are hand made from select seasoned local and North American raw renewable materials.

Maple is the choice wood. This hardwood makes for some interesting grain patterns in the finished product and ages beautifully.

The Shakers originally used maple with quarter sawn Pine lids and bottoms.

Oakville Shaker Works uses Maple with quarter sawn maple lids and bottoms up to the #3 boxes. Quarter sawn maple ensures that the lids do not move too much during the life of the box. Wood is after all a moving thing!

Select veneer Plywood is used for sizes above #3 for the lids and bottoms to ensure they do not split.

Oakville Shaker Works uses Maple. Seen here on the left are raw maple boxes before finishing. On the right are finished boxes. Note the look from blonde to gold once the finish is applied.

The Process...

Many hours of hand work make Shaker boxes come to life. A craftsman must first

have the skill of working with wood and other materials before starting. Shaker Oval

Box Making requires a large commitment in materials simply to start the process of

forming Shaker Oval Boxes.

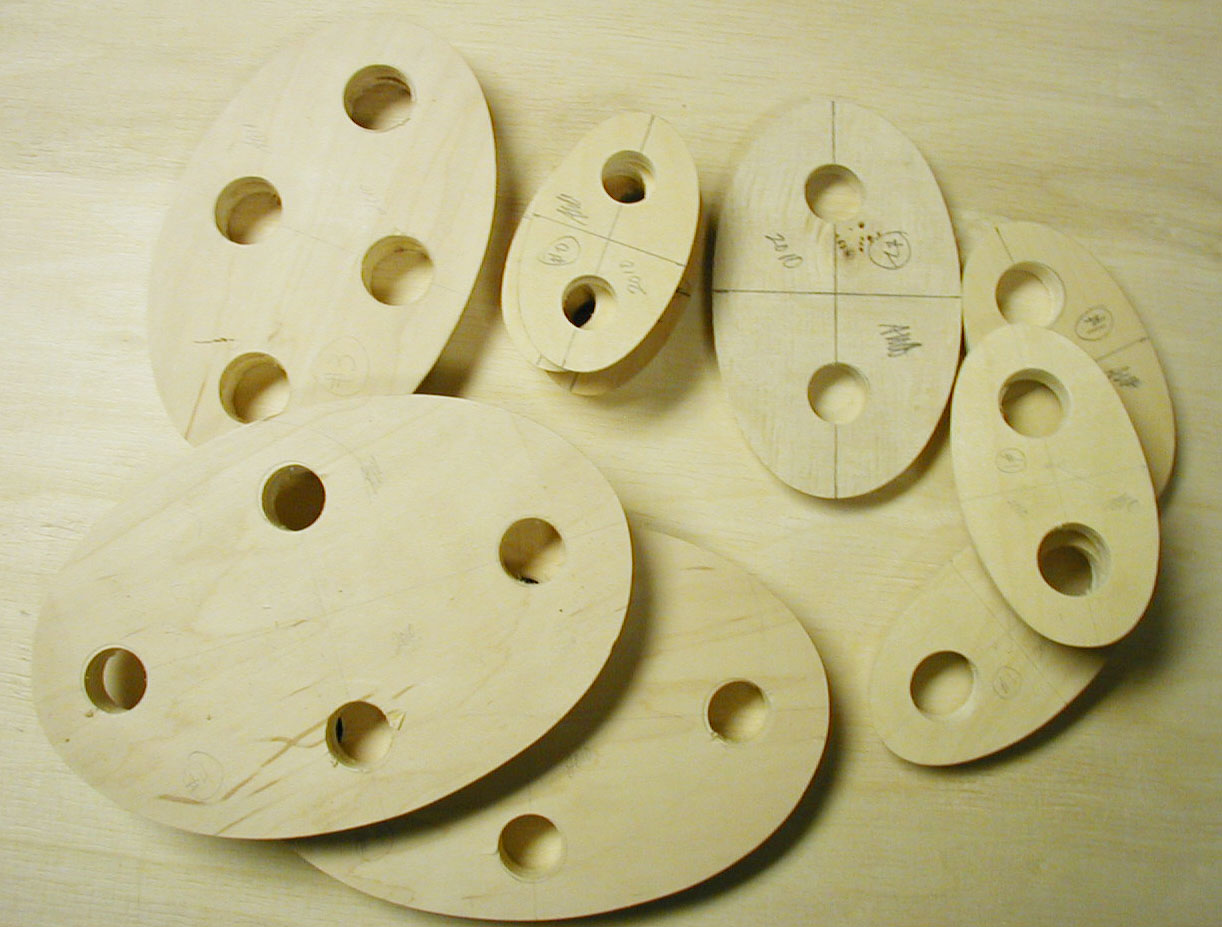

We start with making patterns

using information from Antique

shaker boxes. These are created to

manufacture the bending forms, and

shaping forms which will be used.

These forms are often made of thin

plywood or metal.

The raw material (Maple) is cut to size either on the bandsaw or table saw depending

on the size required. A Bottom band

is cut and a Top band is also cut to

make each box. The material is

sized and sanded ready to be bent.

The ends which are not seen inside

the box are tapered on the sander

and the tack ends are drilled and

swallow tails cut to prepare the

bands for assembly. The cut and

sanded material is immersed in

very hot water for some time,

until the wood becomes pliable and

may be bent on a form without

breaking. Each size box requires a

separate form to bend and each size

box requires two separate shaping Bandsawing the bands

forms to hold the material in shape while it cools and dries.

The maple or other material is bent using the bending form and then the material is put together with copper tacks. Once bent and tacked, two shapers, top and bottom are inserted into the bottom band to hold the shape until cool and dry. the top band is wrapped around the bottom bent band to form the top of the box and tacked in the same way as the bottom. It is then replaced on the bottom band to cool and dry.

Once the top and bottom bands have cooled and dried (about 2 days), the shapers are removed and the top and bottom band are sanded once again. The bottom band is then held against a piece of quarter saw (or ply depending on the size) and the bottom marked out. This is then cut on the bandsaw, oversized and sanded with a negative bevel to the pencil mark, to create a small cork like bottom which is sanded and tested until it fits the bottom perfectly. The top is created in the same way using the top band as the template.

Once the top and bottom are cut and installed, they are held in place with small hardwood toothpicks. A hole is drilled through the sides of the bottom and top band and into the bottom and lid material, which then accepts small wooden toothpicks which are driven in with a tack hammer. This holds the tops and bottoms in place and allows the wood some movement as the seasons change or the humidity of the area changes.

Again the completed raw box is sanded and a finish is then applied.